Critical Inspection Procedures for Inflatable Bottles

Documentation Verification

Check manufacturer certifications (ISO, DOT, UN compliance)

Review Material Safety Data Sheets (MSDS)

Verify batch/lot numbers and production dates

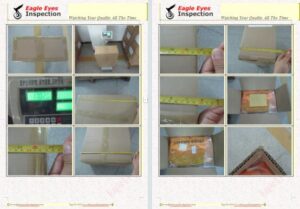

Visual Inspection

Examine exterior for dents, corrosion, or weld defects

Inspect valve integrity and protective caps

Confirm legible permanent markings (capacity, pressure rating, gas type)

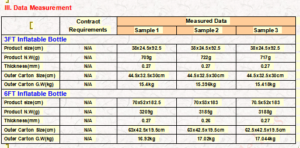

Dimensional & Weight Checks

Verify canister dimensions against specifications

Conduct tare weight verification

Pressure Testing

Hydrostatic test certification validation

Check pressure relief device functionality

Ultrasonic thickness testing (for refillable units)

Leak Testing

Bubble test at valves/seams

Electronic sniffer detection for toxic gases

Material Verification

Spectrometer analysis of alloy composition (if applicable)

Liner inspection for composite cylinders

Valve & Regulator Inspection

Thread gauge verification

Cleanliness inspection for medical/specialty gases

Safety Compliance

Verify transport safety certifications

Check proper labeling (hazard symbols, multilingual warnings)

Sampling Testing

Gas purity analysis (for pre-filled units)

Residual moisture/oil content testing

Packaging Evaluation

Check palletization/securing for transport

Verify anti-corrosion protection