Take a full packed random carton from the master cartons as testing sample, test it on area with a flat and hard floor. Drop the carton from the selected height 10 times from different sides.The products must be checked for

defects before testing to ensure normal functionality and packaging.

Usually, ISTA 1A (International Safe Transit Association) is widely adopted, its standard suits as below:

Scope: For all products with regular master cartons

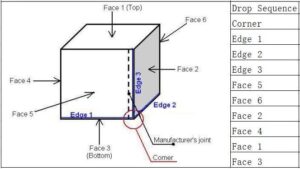

Testing method: 1 corner(weakest corner), 3 edges for the same corner (Edge 1, 2,3 ), 6 faces (5,6,2,4,1,3).

Drop Height Standards:

ISTA 1A suits for package weight 68kg or less, drop test height per below chart:

| English | Metric | ||

| Package Weight | Drop Height | Package Weight | Drop Height |

| 1-20lb | 30 inches | 1-9kg | 76cm |

| 21-40lb | 24 inches | 10-18kg | 61cm |

| 41-60lb | 18 inches | 19-27kg | 46cm |

| 60-100lb | 12 inches | 28-45kg | 30cm |

| 101-150lb | 8 inches | 46-68kg | 20cm |

ISTA 1B suits for package weight over 68kg, drop test at fixed height per below chart:

| English | Metric | ||

| Package Weight | Drop Height | Package Weight | Drop Height |

| Over 150lb | 5.9 inches | Over 68kg | 15cm |

Checking after Drop Test:

Open the carton to verify the condition of products and packaging inside the carton.

Pass: No damage or breakage to packaging. No functionality or safety issues found with the product.

Fail: Deformation, scratches, dents or other damage to products inside,products are not functional after drop test.

Pending: Damage to export cartons/ inner/retail boxes, but the product remains intact.

Carton drop test is very valuable when done on your first shipment and it can be performed as part of the pre-shipment inspection. By including it in your pre-shipment inspection, you can help ensure that the cartons you use are less likely to rupture and cause damage to your products and packaging during transit and rough handling.