PSI quality control Inspection process for Balloons

1. Material Quality

Verify that the materials used (e.g., latex, Mylar, or other polymers) meet the specified standards and are free from harmful substances (e.g., phthalates, heavy metals).

Check for material consistency, ensuring there are no thin spots, holes, or irregularities that could affect durability.

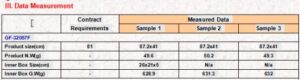

2.Size and Dimensions

Measure the balloons to ensure they match the agreed-upon dimensions (e.g., diameter, length, or volume).

Confirm that the size tolerances are within acceptable limits as per the product specifications.

3.Printing and Design

Inspect the printing quality for clarity, color accuracy, and alignment.

Ensure that designs, logos, or text are free from smudges, scratches, or misprints.

Check for consistency across the batch.

4.Sealing and Seams

Examine the seams and seals for strength and uniformity.

Ensure there are no leaks, weak spots, or incomplete seals that could cause deflation.

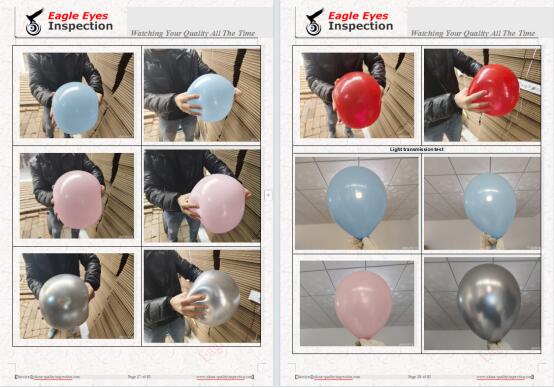

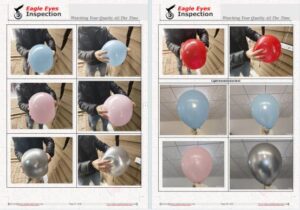

5.Inflation and Durability

Inflate a sample of balloons to their recommended size and check for:

Proper inflation without bursting.

Consistent shape and elasticity.

Ability to hold air or helium for the specified duration.

Test for resistance to popping under normal handling conditions.

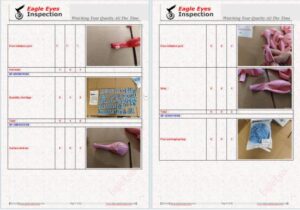

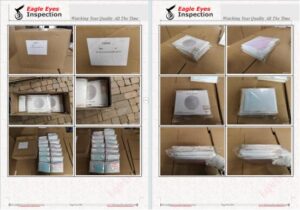

6.Packaging

Verify that the packaging is intact and protects the balloons from damage during transit.

Check that the packaging includes proper labeling, such as product name, size, quantity, and safety warnings.

Ensure compliance with international packaging regulations (e.g., suffocation warnings for children).

7. Safety and Compliance

Confirm that the balloons meet safety standards (e.g., EN 71, ASTM F963, or other relevant certifications).

Ensure compliance with regulations for specific markets (e.g., REACH, CPSIA).

Check for choking hazard warnings and age-appropriate labeling.

8. Quantity and Sampling

Perform a quantity check to ensure the co rrect number of balloons per package and per shipment.

Use AQL (Acceptable Quality Level) sampling methods to inspect a representative sample from the batch.