Parking Barrier Quality Control Inspection Service

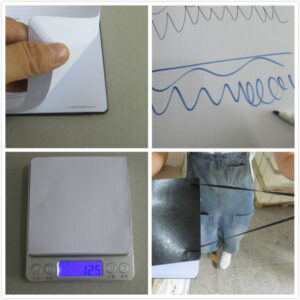

Some common factors for parking barrier quality control: Appearance Quantity check Measurement(weight & size) Basic function check Screw fitting test Key function test Charge test Barries must work correctly on remote controls Barcode scan Drop test 3M tape test for Logo