A4 Photocopy Paper Quality Check Inspection In Liaocheng city

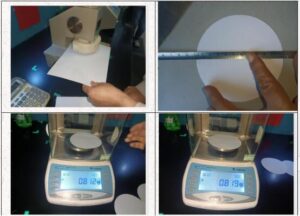

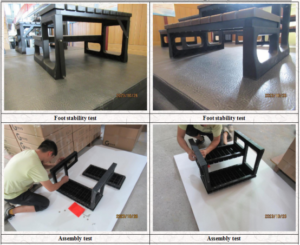

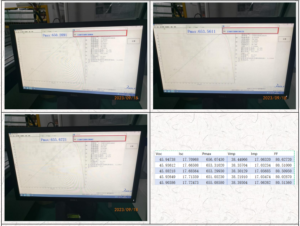

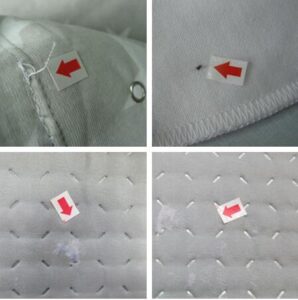

PSI process for Paper Quality Control in LIAOCHENG; Product quality inspection; Including checking product workmanship, whether there are defects, color, specifications, size lights, whether they meet customer order requirements.Check the paper smoothness, integrity, color is consistent with the order requirements. Check the number of unordered sheets and verify the product size. Measured data(Product size,Outer Carton size) Special test for paper products. Packing check(color box,out cartons.) Checking whether the package…