When we buy any product, it is very important to check whether the product we buy meets our expectations. This is because bad products can lead to safety problems, waste of money and time, and may even cause legal problems. In this case, inspection is crucial, especially for goods that involve large quantities of goods or need to be transported over long distances.

Coffee Percolator quality control process:

Randomly Selected Samples:

Random sampling from different locations of different samples, sample test reasonable distribution to each style.

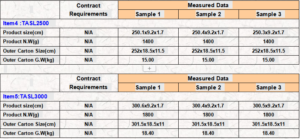

Product quantity check:

Check quantity of all received products or re-check weight, check whether quantity of delivered goods accord with ordered quantity.

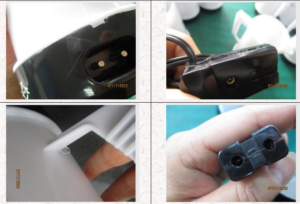

Product quality check

Check product workmanship, surface scratches, holes, stains, true etc. Whether the color meets the requirements of customer order.

Check Data Measurement;

Special tests:

1.Basic Function check;

2.Level Test;

3.3M test;

4.Rub Test;

5.Smell test

6.Barcode Scan test

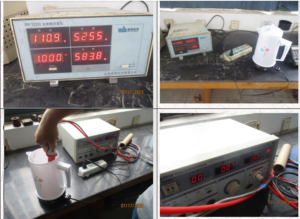

7.Hi-pot test

8.Inter check

9.Power check

10.Actual function test

11.Power cord strength check

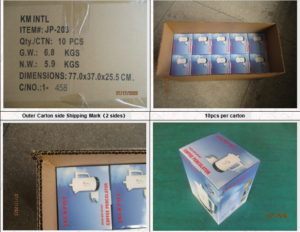

Packing check(color box,out cartons.)

Checking whether the package is fit for transport and meets customer requirements

Inspection Report

Eagle Eyes Quality Inspection Co.,Ltd. will send you a report within 1 working day after the inspection. The content in the report is a summary and presentation of the inspection work, so that you can clearly understand the true condition of the goods.

Inspection can also protect the rights and interests of consumers. When consumers buy and use products, they have the right to know the quality and reliability of what they are buying. If there is any defect or problem with the product, then the consumer has the right to return it or claim compensation. By inspecting goods, you can ensure that consumers receive high quality products and maintain your business reputation.