Eagle Eyes conducts thorough Container loading supervision (CLS) as an essential component of the export process, particularly for shipments from China. This includes carefully verifying the quantity, style, packaging, and overall condition of all products loaded into containers. The goal of CLS is to maintain consistency, protect products, ensure proper sealing, and comply with shipping standards. This comprehensive overview will explore Eagle Eyes approach to Container loading supervision, highlighting its importance and the different aspects of inspection covered.

Why Conduct Container Loading Supervision?

Ensure that your cargo is loaded and shipped satisfactorily with Container Loading Supervision. Our comprehensive inspection report verifies that your goods are loaded according to your specifications, providing you with peace of mind knowing your cargo is in expert hands and will arrive safely at its destination.

Container Loading Inspection in China: A Key Step for Safe Shipments

Steps in Container Loading Inspection

The container loading inspection process includes various steps to guarantee accuracy prior to shipment. The following are the primary steps that are carried out during this inspection.

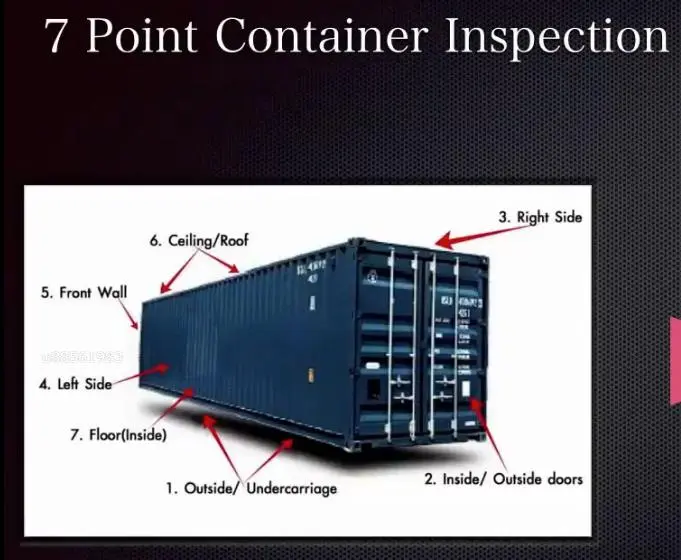

1. Checking the Container

Before loading begins, the inspector examines the shipping container. They check for:

- Holes, rust, or damage

- Dirt, moisture, or odors inside the container

- Proper locks and seals to prevent tampering

2. Verifying Product Quantity

During the loading process, inspectors carefully count the items to ensure that they match the order. If any items are missing or there are extras, the issue is immediately reported and addressed.

3. Sampling Product Weight

The merchant performs weight verification on random items to ensure they meet the expected weight, preventing businesses from shipping incorrect products.

4. Inspecting Packaging and Labels

Effective packaging is crucial for safeguarding products. Thorough inspections ensure that:

- Handling instructions are visible

- Labels contain correct product descriptions and shipping details

- The packaging materials are strong and suitable

5. Supervising the Loading Process

When loading begins, inspectors make sure that:

- Fragile products are properly cushioned to prevent breakage

- Heavy items are placed at the bottom to keep the container balanced

- Goods are arranged efficiently to use space well and avoid movement

6. Sealing the Container

Once the goods are loaded, the inspector ensures that the container is sealed properly. This prevents theft or tampering during transport.

Advantages of Container Loading Inspection

Businesses that conduct container loading inspections benefit in several ways. Some of the main advantages include:

5. Preventing Loss and Theft

Performing a thorough inspection guarantees the safe and secure loading of all items, while also verifying the proper sealing of the container to prevent theft during transportation.

3. Increasing Customer Satisfaction

When consumers receive their purchases in pristine condition, they are more inclined to have faith in and consistently make purchases from the enterprise.

2. Avoiding Costly Shipping Mistakes

In the event of damaged or incorrect products being shipped, businesses may be required to replace them, resulting in increased costs. Conducting an inspection can prevent such errors from occurring.

1. Ensuring High-Quality Shipments

By inspecting merchandise prior to shipping, merchants can ensure that only high-quality goods are delivered to their customers. This practice minimizes the likelihood of complaints and returns.

4. Following Shipping Rules

When shipping goods internationally, it is important to follow country-specific regulations regarding proper packaging and labeling. By adhering to these guidelines, customs inspections can be avoided and the likelihood of shipment rejection is decreased.

Container Loading Inspection Checklist

nspectors follow a container loading inspection checklist to make sure they do not miss any important steps. This checklist includes:

Inspectors adhere to a checklist while loading containers to ensure all crucial steps are accounted for. This thorough checklist covers:

✔ Inspecting packaging for damage or mistakes

✔ Checking if the container is clean and in good condition

✔ Supervising loading to ensure items are placed correctly

✔ Weighing samples to check for accuracy

✔ Verifying that the number of products matches the order

Why Container Loading Inspection is Important?

The inspection of shipments before they leave the factory is crucial for businesses. This step ensures that their products are delivered in optimal condition. There are several vital reasons for conducting such inspections:

1. Checks the Condition of the Container

Damaged containers can lead to shipping issues, specifically if they have holes, rust, or leaks. To ensure the safety of the products inside, containers are carefully inspected by experts for cleanliness, dryness, and overall suitability for shipping.

2. Protects Products from Damage

Correctly packing and loading products is crucial for preventing damage during transport. It is important to place heavy items at the bottom and secure fragile items. Inspectors thoroughly check the packaging’s strength to ensure proper protection of the goods.

3. Verifies Packaging and Labels

Ensure proper packaging and labeling procedures are adhered to for each shipment to avoid potential delays during customs inspections. It is crucial that labels contain accurate information and packaging is secure to avoid any issues.

4. Ensures the Right Number of Items Are Shipped

If a shipment is incomplete, customers may not receive what they ordered. The goods are counted by inspectors to verify that everything matches the order. This practice is crucial for businesses to avoid losses and maintain positive relationships with their buyers.

5. Helps Avoid Shipping Delays

The shipment may be held by customs officials in the case of any issues. Delays can result from this, which can prove to be expensive for businesses. To prevent such delays, a thorough inspection is necessary to comply with all regulations and minimize risk.

Significance of Container loading supervision:

Accurate container loading supervision is crucial for guaranteeing the quality and dependability of goods exported from China. Here are some reasons that demonstrate its importance:

1. Second-hand Equipment or Scrap Metals: When handling high-risk items, such as second-hand equipment or scrap metals, it is crucial to follow proper procedures in order to minimize the risk of damage, contamination, or safety hazards during transit. This includes verifying the condition, using appropriate packaging, and employing proper loading techniques. These practices are especially important in order to ensure a safe and successful transportation process.

2. Fraud and Trade Dispute Prevention: CLS is an effective solution for preventing fraudulent activities by ensuring the accuracy of goods being shipped. Through thorough verification of quantity, conformity, and packaging, CLS effectively reduces the likelihood of receiving substandard or counterfeit products. Additionally, it serves as critical documentation in the event of any trade disputes, serving as evidence of the loading process.

3. Unclear Quantity of Shipment: When the amount of goods is uncertain, it is crucial to use CLS correctly. The inspection can accurately verify the quantity and prevent misunderstandings while promoting transparency between buyers and suppliers.

4. Delivery Record Accuracy: The CLS solution offers comprehensive delivery data, giving CLSents complete insight and accountability for their shipments. This data is crucial for inventory tracking, supply chain management, and addressing customer inquiries.

5. New Suppliers: CLS helps mitigate moderate risks associated with product quality and consistency when collaborating with new suppliers, ensuring the products meet buyer’s specifications and expectations with an extra layer of assurance.

What is Container Loading Supervision?

Container Loading Supervision (CLS), also referred to as Container Loading Inspection (CLI) or Container Loading Check (CLC), is a quality control procedure that verifies the proper handling of goods during the packing process. It is a crucial step in your product quality control system before your goods are shipped overseas from your supplier’s factory in Asia. The China Look Group team highly advises utilizing our CLS service to prevent any unexpected issues upon arrival at the final destination.

Eagle Eyes’s Approach to Container loading supervision:

Eagle Eyes utilizes a thorough method for Container loading supervision in China, employing experienced inspectors to oversee the loading and ensure that all goods meet quality standards. The CLS process at Eagle Eyes consists of several key steps.

1. Export Carton Quality: The quality of export cartons is evaluated to ensure they meet the required standards for secure transport. Evaluators check for strength, stability, and appropriate cushioning materials.

2. Quantity Verification: Inspectors verify that the loaded products match the agreed-upon quantity to prevent discrepancies and maintain accurate delivery records.

3. Reasonable Placement of Export Cartons:Inspectors ensure the proper placement of export cartons in containers, maximizing space utilization and maintaining stability during transit.

4. Product Conformity: Inspectors check if the loaded products match the approved samples or specifications to ensure consistency and adherence to quality standards. This process is crucial for maintaining high-quality standards and consistency.

5. Container Quality: Inspectors assess the containers’ condition to guarantee they are free of damage, clean, and appropriate for transporting goods. This process aims to prevent any contamination or harm during transit.

6. Packaging, Labeling, and Shipping Marks: The packaging, labeling, and shipping marks of each product are carefully inspected by Eagle Eyes inspectors to confirm compliance with both CLSent’s requirements and international shipping regulations.

7. Loading Process Supervision: As professionals in the industry, Eagle Eyes inspectors carefully monitor the loading process and ensure that the correct handling techniques are implemented, mitigating any risk of product damage or misplacement.

8. Shipping Document Verification: Prior to sealing the container, inspectors conduct a comprehensive review of all shipping documents to ensure accuracy and completeness. This includes packing lists, invoices, and any other required paperwork.

Common Problems Found During Container Loading Inspections

During the shipping process, certain issues may be identified by inspectors that can potentially cause problems. Some common problems that may arise include:

- Damaged Containers: Containers with cracks, rust, or leaks that can harm products inside.

- Incorrect Quantities: If items are missing or extra, it can lead to financial losses.

- Weak Packaging: Poor packaging can cause products to break before they reach their destination.

- Wrong Labels: Missing or incorrect labels can cause delays at customs.

- Bad Loading Practices: Unevenly loaded containers can lead to damaged goods during transport.

By detecting these issues early on, companies can address and resolve them prior to the shipment being sent out from the factory.

Where is Container Loading Supervision in China Conducted?

This service involves supervising the loading of containers at the supplier’s warehouse, the forwarder’s warehouse, or any other facility where your goods are stored before being shipped internationally.

When is Container Loading Inspection Conducted?

The Container Loading Inspection is completed once your entire order has been packed and is prepared for shipping by container.

Our company values proper container loading, which is why we perform a comprehensive pre-loading inspection to guarantee correct loading. This inspection covers the container’s condition, shipping details, documentation, and loading list, as well as the state of cartons, pallets, and pallet packing.

Eagle Eyes’s Container Loading Supervision (CLS) service in China guarantees the safe and accurate shipment of goods. Our comprehensive approach includes verifying quantity, conformity, packaging, labeling, and shipping marks, minimizing risks such as fraud, trade disputes, and quality issues. As industry experts, our professional and objective tone ensures a secure and trustworthy environment for your products. Utilizing percentages, facts, and numbers, Eagle Eyes’s CLS is an essential process for exporting goods from China.

In certain circumstances, the use of CLS is highly advantageous. This includes cases where thorough delivery documentation is necessary, shipment quantities are unclear, or when dealing with untested vendors or potentially problematic materials like used machinery or scrap metal. CLS is essential for maintaining transparency, avoiding confusion, and protecting the buyer’s best interests.