The key inspection points for metal accessories typically include the following aspects:

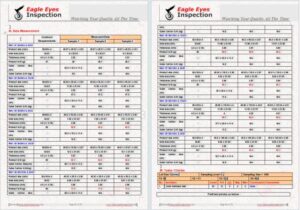

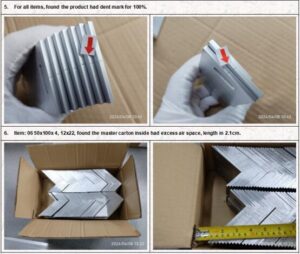

1. Dimensional Inspection

Verify that all dimensions (length, width, thickness, hole sizes, etc.) meet the design specifications.

Check tolerances to ensure consistency.

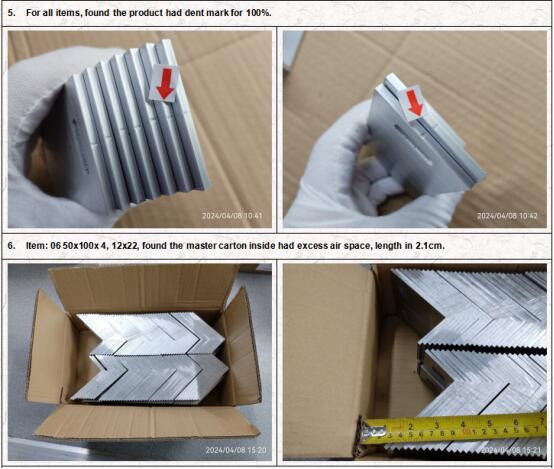

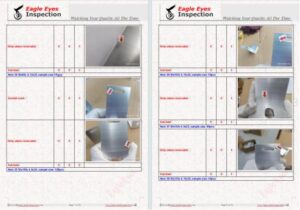

2. Surface Quality

Inspect for scratches, dents, rust, oxidation, or other surface defects.

Ensure proper plating/painting (e.g., no peeling, uneven coating, or discoloration).

3. Material Verification

Confirm the correct metal type (e.g., stainless steel, aluminum, brass) and grade.

Check material certificates (if required) for compliance with standards.

4. Functional Testing

Test moving parts (e.g., hinges, locks) for smooth operation.

Verify thread engagement (if applicable) for screws, nuts, and bolts.

5. Strength & Durability

Conduct hardness tests (if required).

Check weld quality (no cracks, porosity, or weak joints).

6. Corrosion Resistance

Perform salt spray tests (if applicable) to verify coating durability.

Ensure proper passivation for stainless steel parts.

7. Marking & Labeling

Verify part numbers, batch codes, and manufacturer markings.

Check for compliance with industry standards (e.g., RoHS, REACH).

8. Packaging & Documentation

Ensure proper packaging to prevent damage during transit.