Factory Quality Inspection for Glass Bottle in Yuncheng, Heze;

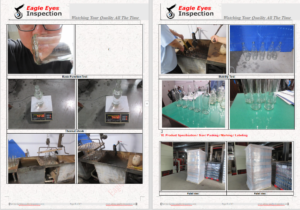

Randomly Selected Samples:

The purpose of this inspection is to ensure that the products meet the specified standards and requirements before they are approved for shipment or use.

AQL sampling inspection is a statistical method that randomly selects a small number of products (samples) from a batch of products for inspection to determine whether the batch of products are qualified.

Product quality inspection;

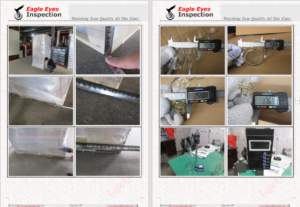

Product workmanship, color, specifications, function, barcode, etc will be checked based on customer’s requirements.

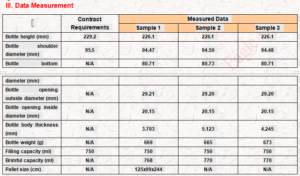

Measured data(Product size,Outer Carton size)

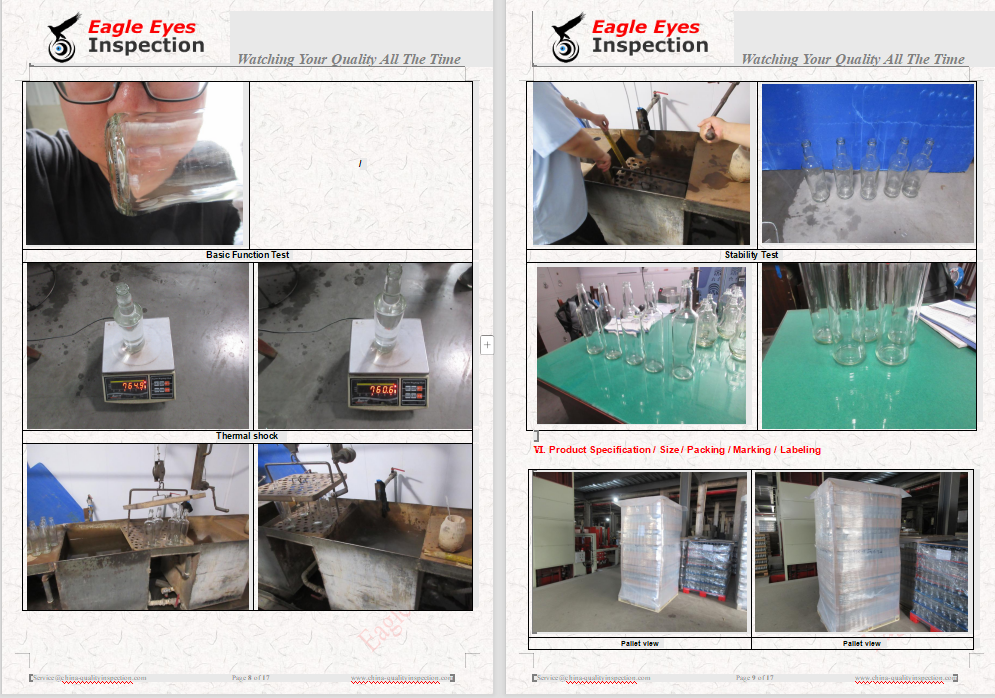

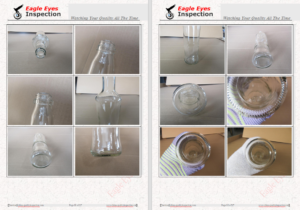

Special test for Glass Bottle

- Logo/Printing 3M Tape test

- Basic function check(Functions on product specification work)

- Barcode Scan

- Wobbling test

- Hot water test

- Polarizing stress test

- Capacity test

- Impact resistance test

- Leakage test

- Flatness check

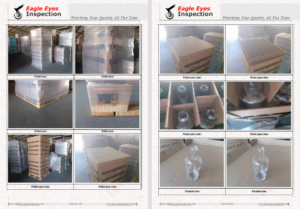

Packing check(color box,out cartons.)

Check whether the package meets customer requirements, determine the size and weight of the package, and check whether the package is suitable for product transportation.

Inspection Report

Once the pre-shipment inspection is completed, a report will be provided within 24 hours, an overview of key findings, and a detailed account of the inspection results. All the original photos, videos, original testing data are contained, so you can see exactly what was discovered.