PSI process for Hydrogen Water Bottle;

Randomly Selected Samples:

AQL sampling inspection is a statistical method that randomly selects a small number of products (samples) from a batch of products for inspection to determine whether the batch of products are qualified.

Product quality inspection;

Product workmanship, color, specifications, function, barcode, etc will be checked based on customer’s requirements.

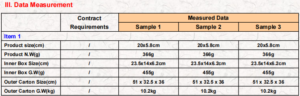

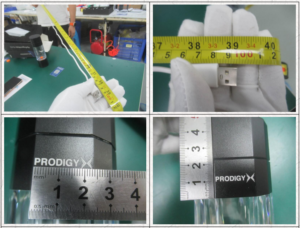

Measured data(Product size,Outer Carton size)

Special test for Hydrogen Water Bottle

1 Logo/Printing 3M Tape test

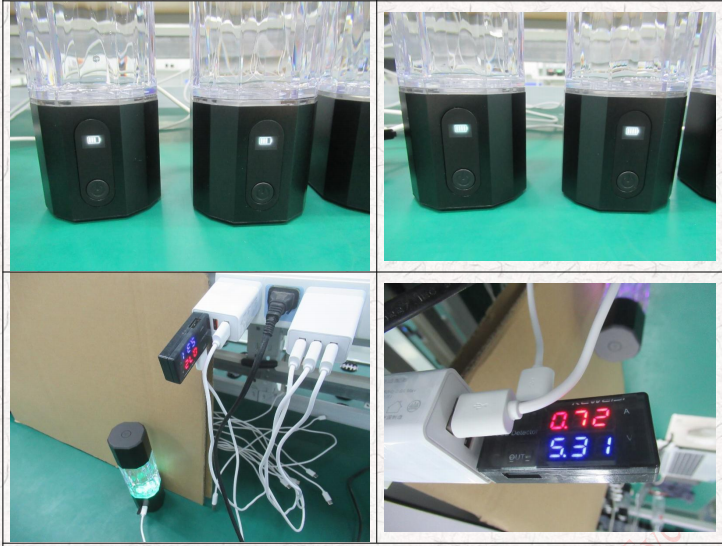

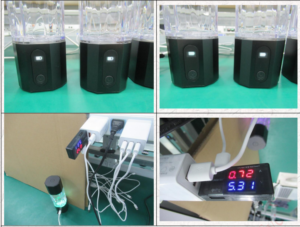

2 Basic function check(Functions on product specification work)

3 Barcode Scan

4 Battery voltage test

5 Charging test

6 Smell test

7 Capacity test(208ml)

8 Pour away the water test

9 Leakage test

10 Flatness check

11 Time check

Packing check(color box,out cartons.)

Checking whether the package is fit for transport and meets customer requirements

Inspection Report

Once the pre-shipment inspection is completed, a report will be provided within 24 hours, an overview of key findings, and a detailed account of the inspection results. All the original photos, videos, original testing data are contained, so you can see exactly what was discovered.