PSI process Aluminum sheet ;

Aluminum Plate Inspection Process

Document Verification

Check material certificates (e.g., EN 10204 3.1/3.2, ASTM B209).

Verify mill test reports (MTRs) for alloy grade, temper (e.g., 6061-T6), and standards compliance.

Visual Inspection

Surface defects: Cracks, scratches, dents, or discoloration.

Coating quality (if applicable): Evenness of anodized/painted layers.

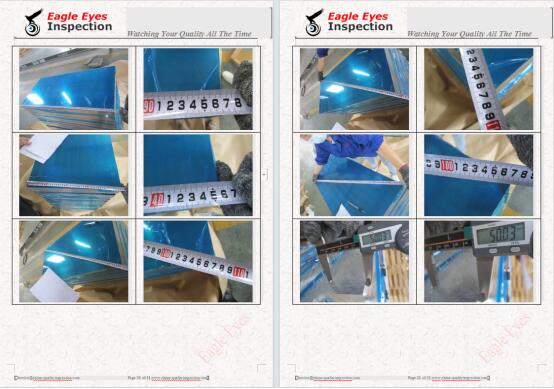

Dimensional Check

Thickness, width, length (± tolerance per ASTM/ISO standards).

Flatness and edge straightness.

Material Testing

Hardness test: Rockwell/Vickers (e.g., HRB for soft alloys).

Tensile test: Yield/ultimate strength (per ASTM E8/E21).

Chemical composition: Spectrometer analysis for alloy elements (e.g., Si, Mg, Cu).

Non-Destructive Testing (NDT)

Ultrasonic testing: Internal voids/delamination.

Eddy current: Surface cracks (for conductive alloys).

Corrosion Inspection

Salt spray test (ASTM B117) for coated plates.

Pitting resistance check (if specified).

Packaging & Marking

Confirm protective packaging (anti-scratch film, moisture-proof).

Verify labels: Alloy, temper, batch no., and supplier details.