Inspection Process and Key Points for Liaocheng Metal Fittings Kit

1. Pre-Inspection Preparation

Review Documentation: Check product specifications, drawings, QC standards, and purchase order requirements.

Sampling Plan: Follow AQL (Acceptable Quality Level) standards (e.g., ANSI/ASQ Z1.4) for sampling size.

Tools Preparation: Calipers, micrometers, hardness testers, surface finish gauges, and packaging inspection tools.

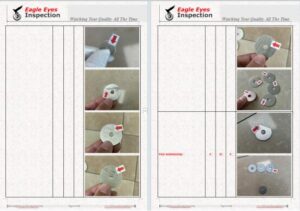

2.Dimensional Inspection

Critical Dimensions: Verify key dimensions (e.g., thread pitch, hole diameter, thickness) against technical drawings.

Tolerances: Ensure compliance with ±0.1mm or specified tolerances.

Interchangeability: Test assembly compatibility with mating parts if applicable.

3. Material & Finish Verification

Material Grade: Confirm metal type (e.g., stainless steel 304, carbon steel) via material certificates or spectrometer testing.

Surface Treatment: Check plating (zinc, nickel), powder coating, or anodizing for adhesion, thickness, and uniformity.

Rust/Defects: Inspect for scratches, oxidation, burrs, or uneven coatings.

4. Functionality & Durability Tests

Load Testing: Apply force to load-bearing parts to ensure they meet strength requirements.

Thread Engagement: Test screw/bolt threads for smooth engagement without cross-threading.

Corrosion Resistance: Conduct salt spray test (if required) per ASTM B117.

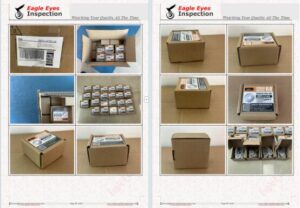

5.Packaging & Labeling

Inner Packaging: Verify anti-rust paper, bubble wrap, or dividers to prevent scratches.

Outer Carton: Check carton strength, moisture-proofing, and shipping marks.

Label Accuracy: Ensure part numbers, quantities, and barcodes match the order.

6. Documentation & Reporting

Non-Conformance: Record defects (critical/major/minor) with photos and measurements.

Inspection Report: Issue a detailed report including pass/fail status and corrective actions.

Key Notes:

Supplier QC Coordination: Align inspection criteria with the supplier beforehand.

Safety: Wear gloves/PPE when handling sharp edges.

Defect Threshold: Define acceptable defect rates (e.g., 0% critical, ≤2.5% major defects).

Example Defect Classification:

Critical: Cracks, incorrect material.

Major: Dents, poor plating.

Minor: Minor scratches, packaging misalignment.