PSI process for light product;

Randomly Selected Samples:

Sampling inspection, also known as sampling inspection, is a statistical method that randomly selects a small number of products (samples) from a batch of products for inspection to determine whether the batch of products are qualified.

Product quality inspection;

Including checking product workmanship, whether there are defects, color, specifications, size lights, whether they meet customer order requirements.

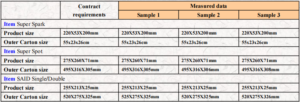

Measured data(Product size,Outer Carton size)

Special test for light products.

1 Hi-Pot test

2 Function and Application test

3 Assembly check

4 Running test (power on)

5 Fatigue Test for all buttons or adjustable parts

6 Torque test

7 Earth Continuity check

8 Internal check

9 Power cord strain relief test (for European) /pull test (for US)

10 Tape check on silk-screen/painting/electroplate

11 Rub check on rating label

12 Power cord strain relief test (lighting)

13 Carton drop test

14 Smell test

15 Color comparison check

16 Polarity test for US market

17 Life test

18 Stability test

19 Fitness check for lamp and lamp holder

20 Series connection test

21 Vibration test

22 Power consumption of bulb

23 Luminous efficiency check for energy safe bulb

24 High and low temperature working test

25 Color temperature of bulb check

26 Reliability Test for all lamps

27 Spare bulb checking

28 Power consumption check (input power)

29 Pull test: (collar and lamp holder) –light chain

30 Pull test: (Supply cable and plug) –light chain

Packing check(color box,out cartons.)

Checking whether the package is fit for transport and meets customer requirements.

Inspection Report

The report shows the situation at the inspection site. Check and verify that the goods meet the requirements of size, weight, packing and workmanship according to the information provided by customer. Work is good, function test is normal. After reading the report, customers can accurately judge whether the goods meet the requirements of the order.