QC check process for power controller in Bazhou Langfang;

Randomly Selected Samples:

AQL sampling inspection is a statistical method that randomly selects a small number of products (samples) from a batch of products for inspection to determine whether the batch of products are qualified.

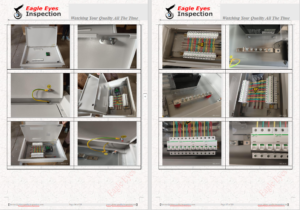

Product quality inspection;

Product workmanship, color, specifications, function, barcode, coating, structure etc will be checked based on customer’s requirements.

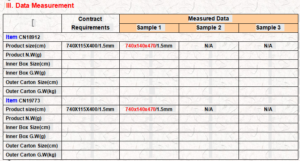

Measured data(Product size,Outer Carton size)

Special test for power controller

1.Basic function check (Functions on product specification work )

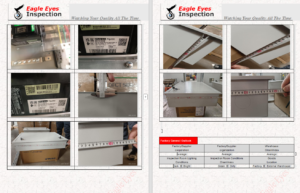

2.Product size inspection

3.Coating: Ensure the coating is even, without peeling or bubbling.

4.Structure: Inspect the sturdiness of the box, and ensure doors, locks, hinges, and other components are flexible and reliable.

5.Internal Components:

5.1 Component Installation: Confirm that components such as circuit breakers and contactors are securely installed and correctly wired.

5.2 Component Brands and Specifications: Verify that the brands, models, and specifications of the components comply with the contract requirements.

Inspection Report

Once the pre-shipment inspection is completed, a report will be provided within 24 hours, an overview of key findings, and a detailed account of the inspection results. All the original photos, videos, original testing data are contained, so you can see exactly what was discovered.