After deciding the sample size based on inspection standard and AQL tables, here we need to choose the number of products to check.

1. Select the right quantity of cartons

At least the square root of the total number of cartons(Example: at least 8 cartons if there is a total of 63 cartons.), or otherwise defined by client, in the shipment are randomly selected and opened. The inner content is checked for correct quantity and assortment. The samples are selected proportionally from the opened cartons. If the sum of opened cartons can not give the sufficient number of sample size, cartons should be opened until the quantity is met.

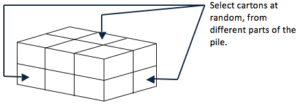

2. Randomly select the cartons from the pallets

Select the cartons randomly, for example, from the front and back, top and down, right, let and inside of the pallet, not just from the same position of the pallet.

If the goods are not 100% packed, also need to select some samples from the unpacked products according to the ratio of packed and unpacked pieces.

For example, if there are 200 pcs among 4000 to be inspected, and there are just 3000pcs packed into cartons, and 1000pcs ready to be packed, have to select 150 pieces from packed cartons and 50 unpacked pieces.

3. Randomly select the products from selected cartons

During the selection of products from cartons, need to randomly pick up the pieces, for example, from each layer or each poly bag of product, to represent the real product quality situation as maximum as possible.