Inspection Process and Key Points for Gaomi Nitrile Gloves

1. Pre-Inspection Preparation

Document Review: Verify product specifications, PO requirements, and quality standards (e.g., ASTM D6319 for nitrile gloves).

Sampling Plan: Follow AQL (Acceptable Quality Level) standards (typically Level II, AQL 1.0/2.5 for major/minor defects).

Tools Preparation: Prepare calipers, weighing scale, tensile tester, visual inspection tools, and leak tester (water filling or air inflation method).

2. Visual Inspection

Surface Quality: Check for holes, tears, uneven thickness, stains, or foreign particles.

Molding & Trimming: Ensure smooth edges, no excessive flashing, or incomplete molding.

Printing & Marking: Verify logos, sizes, and certifications (e.g., CE, FDA) are legible and correct.

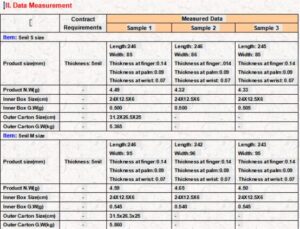

3. Dimensional & Weight Checks

Length/Width/Thickness: Measure with calipers per ASTM standards (e.g., thickness tolerance ±0.05mm).

Weight: Weigh random samples; ensure consistency (e.g., ±0.5g per glove).

4. Physical Performance Tests

Tensile Strength & Elongation: Test using a tensile machine (ASTM D412; typical requirements: tensile strength ≥14MPa, elongation ≥500%).

Puncture Resistance: Check per ASTM F1342 (e.g., puncture force ≥1.5N).

5. Special function test

Barcode Scan

Basic function check (Functions on product specification work )

Water loading test

Pull test

Smell check

Color shading check

Rub test

Carton drop test

6. Chemical & Material Safety

Certificates: Confirm nitrile material complies with FDA 21 CFR 177.2600 or EU 10/2011 for food contact (if required).

Allergen Check: Ensure no harmful accelerators (e.g., MBT, ZDBC) exceed limits.

7. Packaging & Labeling

Inner/Outer Packaging: Verify cleanliness, sealing integrity, and moisture-proof measures.

Label Accuracy: Check batch number, expiry date, size, and compliance markings.

8. Defect Classification

Critical Defects: Holes, chemical contamination (reject entire lot).

Major Defects: Thickness deviation, weak seams (AQL 1.0).

Minor Defects: Minor stains, printing errors (AQL 2.5).

9. Reporting

Inspection Report: Record defects, test data, and non-conformities with photos.

Disposition: Recommend approval/rejection based on AQL results.

Key Focus Areas:

Consistency: Thickness, color, and texture uniformity.

Durability: Tensile strength and leak resistance.

Safety: Compliance with FDA/CE and absence of toxins.