What is PSI?

Pre-shipment inspection refers to the inspection of products randomly selected by inspectors from all order lots for inspection after production has been completed at least 80%. This is your last chance to take corrective action before production is complete and packaging is complete. Pre-shipment inspection can effectively protect you from costly import risks.

All tests were conducted in accordance with the internationally recognized ANSI/ASQC Z1.4 (ISO 2859-1) standard statistical sampling procedure. These comprehensive criteria include: quantity, size, weight, marking, labeling, functionality, overall appearance. After the inspection, Eagle Eyes china inspection company will issue the inspection report.

Why do buyers need to conduct psi?

Ensure that your products’ manufacturing quality lives up to your brand’s standards. A pre-shipment inspection report offers you peace of mind in the knowledge that your products are made to specification, and the final product accurately represents your brand.

PSI process

1.Quantity Verification

The inspectors count the shipping cartons to verify the correct quantity, check the storage environment by taking photos for stock, verify whether any package damaged in stock, and observe the bottom of the package.

2.Random Sampling

Based on the sampling plan, the inspector selects a predefined number of products at randomly and check the quality.

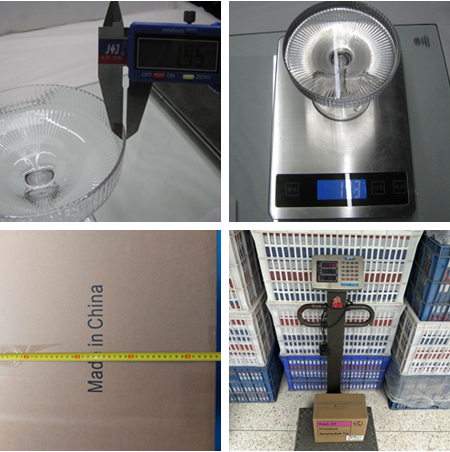

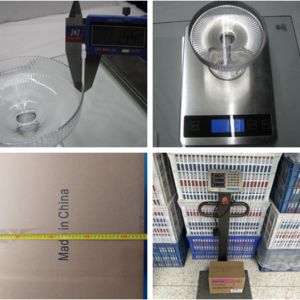

3.Size check, weight check,color box check,outer cartons check.

5.Function and Safety Test

Functional testing refers to functional verification. Based on functional test cases, operational descriptions, and user scenarios, a product’s features and operational behaviors are tested to determine whether the design requirements are met.

4.Packing check-shipping mark check

Packaging is also checked to verify that the correct packing materials are being used to ensure safe transportation, and that correct packaging labels are applied.

PSI Inspection Report

Once the pre-shipment inspection is completed, a report is compiled with a pass/fail/pending result, an overview of key findings, and a detailed account of the inspection results. All the original photos, videos, original testing data are contained, so you can see exactly what was discovered.