Key Inspection Points for Beach Towels (Final Inspection )

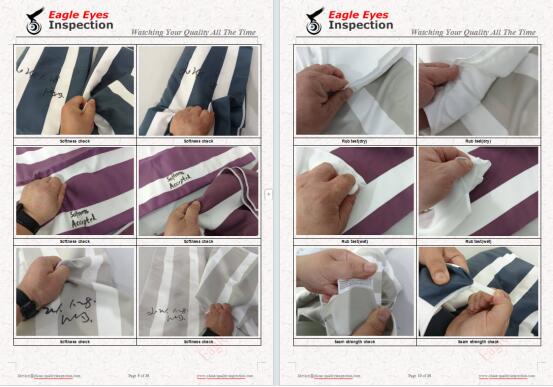

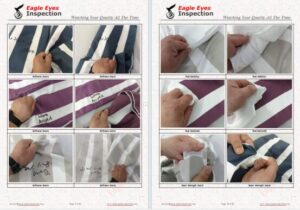

Fabric Quality

Check for consistent texture, thickness, and softness.

No stains, discoloration, or uneven dyeing.

Ensure no holes, snags, or loose threads.

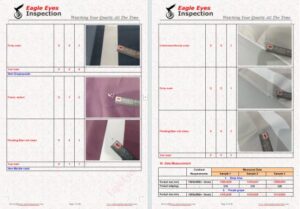

Size & Dimensions

Verify length, width, and thickness meet specifications.

Allowable tolerance: ±2% (or as per buyer’s requirement).

Printing/Embroidery

Colors should match approved Pantone references.

No misprints, smudges, or blurred patterns.

Embroidery must be secure with no loose threads.

Hemming & Stitching

Edges should be evenly hemmed with no fraying.

Stitching must be straight, tight, and without skipped stitches.

Label & Packaging

Correct placement of size/care labels (stitching must be secure).

Barcode/UPC scanning verification (if applicable).

Packaging should be clean, intact, and match order requirements (polybag, tag, etc.).

Functionality

Absorbency test (if required) – towel should quickly absorb water.

Colorfastness check (no bleeding during washing).

Odor & Cleanliness

No unpleasant chemical or mildew smells.

Free from dust, dirt, or manufacturing residues.

Quantity & Shipping Marks

Confirm total quantity matches packing list.

Shipping marks (carton labels) must be correct and legible.

Common Defects to Reject:

Fabric defects (pilling, shrinkage, uneven weave).

Poor print alignment or color deviations.

Loose hems/unraveled edges.

Incorrect packaging or labeling errors.