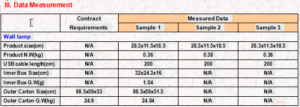

Puyang Wall lamp full check process;

Sampling Plan

1.Increase 100% appearance inspection positions in the production line;100% increase in alignment of weighing test accessories;Added tracking system label control;

2.MIL-STD-1O5E, S-2 for size and function check ,Level II (Normal) for appearance check, Acceptable Quality Level (AQL) = 0 of Critical – 2.5 Major and 4.0 Minor defect.

Viewing distance:30~35cm.

Viewing Time:5~10s.

Viewing Light:Cool fluorescent light with an intensity of 800~1100 lux.

Components can rotate horizontally and vertically.

Key Inspection Points for Wall Lights

Appearance & Workmanship

Check for scratches, dents, discoloration, or surface defects.

Ensure consistent color/finish (e.g., paint, plating, or polish).

Verify logos/labels are correct, legible, and properly aligned.

Surface Classification/Inspection Guidelines/Inspection Conditions/Defect Definitions/Acceptance Criteria/ Rejection Criteria/please refer to(Visual Quality Standard(synthetic rubber glue).

1.No scratches, breakage, leakage, scratch customer complaint history.

2.Refer to the specification, no more welding, virtual welding, less components.

3.No, lack of glue, deformation,wrinkle,poor viscosity.

4.Refer to the specifications, no deformation, multiple welding, virtual welding, less components.

5.Can not plug holes, lack of glue, deformation, external surface scratches and scratches, the lettering is required to be clear without mutilation, no fingerprints or other residue, color must match other components.

6.According to the specifications, the battery has no bulge, damage, wiring errors, and the battery jet code is clear and correct.

7.Check production date and specification, no damage, leakage.

Material Quality

Confirm materials (e.g., metal, glass, plastic) meet specifications.

Inspect for rust, cracks, or poor welding/sealing.

Functionality

Test the switch (if applicable) for smooth operation.

Verify proper illumination (no flickering/dim spots).

Check for overheating after prolonged use (safety critical).

Electrical Safety

Ensure wiring is secure with no exposed conductors.

Test insulation resistance and grounding (if applicable).

Certifications compliance (e.g., CE, UL, RoHS marked).

Packaging & Documentation

Inspect packaging for adequate protection against damage.

Verify user manuals, warranty cards, and accessories are included.

Check labeling (model number, voltage, warnings) matches the product.

Installation Compatibility

Confirm mounting holes/back plate align with specifications.

Ensure screws/brackets are included and fit properly.