The meaning of supervision

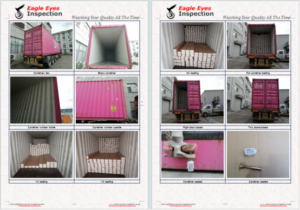

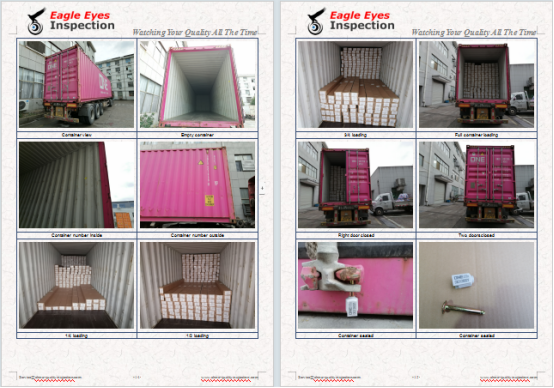

That is, the goods should be arranged for loading, because the workers are not trusted to load, we must arrange people to the loading site to watch the workers loading. – To prevent the workers from damaging the goods by loading them carelessly. The other side

The face can be photographed, so that your customers know the integrity of this product, but also a kind of evidence. Our products must be supervised by someone, in addition to preventing the workers from damaging the goods, on the other hand

Make sure the goods are square.

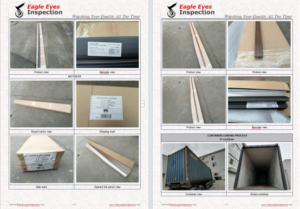

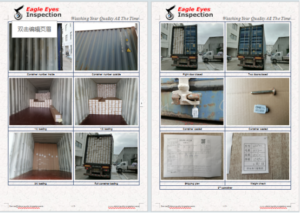

1) Check the cabinet number, license plate number and customs seal number, check whether the cabinet is damaged and leaking;

2) Unpack and check the products in the container again to confirm that the goods to be loaded are correct and whether the outer box is damaged; Check whether the cabinet is damaged, dented and clean. The code in the upper right corner of the cabinet is the cabinet number.

3) Cabinet arrangement; According to the number of square of the goods loaded and the number of goods ordered by the customer, it is simple to say how many outer boxes are installed in each row, and how to install more space saving (in general, horizontal and vertical rows of outer boxes will get different results). Then multiply the number of rows M by the number of rows N in a cabinet to get an estimate of how many can be held in this cabinet. Then compare the number of orders placed by the factory to conclude whether it can be filled. Generally, it is necessary to ensure that all the goods of the customer can be loaded, and it is not finished next time.

4) In case of rainy days, pay special attention to not wet the outer box, so the container is generally selected in the weather without rain, if it is rainy, it must wait for the rain to stop or work in a place with shelter.

5) If time permits, it is best to send a drawing to the customer for confirmation, and then use the seal to lock the cabinet after the customer’s final confirmation.